KINGMAX GREAT TOWEL

KINGMAX is dedicated to supply the best microfiber towels to our customers.

We are confident to announce that KINGMAX Great Towel is the best microfiber towel product you can find in the market. Presenting a qualified sample is easy, but keeping high standard of product quality is hard in the long term. KINGMAX has standardized the production procedures and relative regulations and recruited a QC team so as to stabilize our quality performance.

Every product shipped to our customers is from our standardized manufacturing workshop after QC and therefore meet the requirements. To analyze its advantages, let’s take a look at its material, production and features one by one.

RECYCLED MICROFIBER & VIRGIN MICROFIBER

100% RPET Recycled Microfiber

KINGMAX is qualified to provide all series of products made from rPET recycled microfiber. With certification of Global Recycled Standard (GRS), we are proud to announce that all microfiber towels we sold to customers are traceable from raw material sources to the manufactures to guarantee the TURE RECYCLED PET BOTTLES.

Why should we purchase recycled microfiber towels rather than regular microfiber towels? One of main reason is that recycled post-consumer PET bottles being converted into new microfiber towels consumes far less energy than producing microfiber towels from virgin plastic directly. In fact, this recycling-producing process reduces approximately 31% of water scarcity, 44% of energy power, 12% of chemistry and therefore 26% CO2 emissions.

This circular approach will undermine the negative impacts of human activities, reduce resource shortage and make our small but meaningful contributions to environmental protection. KINGMAX Great Towel is a recycled microfiber towel. Turning to rPET Recycled microfiber is a smart and eco-friendly choice, for our sustainable future.

Standard Production Lifts Microfiber Cloth Manufacturing Capacity

In order to maintain the stable output and high efficiency of microfiber cloth production, KINGMAX has introduced several standardized automatic production lines and formed relative rules and regulations in the towel factory.

KINGMAX Great Towel is produced in high standard hygiene production lines, compared to its counterparts in the market. Those factories follow no rules or rely on simple labor with low efficiency. While, every productive procedure of KINGMAX Great Towel, from weaving, dyeing, cutting, stitching, packaging to shipping, is high mechanic and strictly follows the standard manuals.

Quality Control is also one of the most significant production procedures KINGMAX values. On-site QC and end-product QC are both compulsory to keep the high-level of quality and therefore earn customer’s trust in the long term.

Under such high standard, our microfiber towel production capacity can easily meet various customized needs, whether from a professional cleaning cloth purchaser or a commercial or household wash towel wholesaler.

Safe and Free of Harmful Chemical Substance

Have you had the experience that you sensed a bad smelling when open a pack of microfiber towels? This kind of smelling will not easily disappear after weeks. Besides of the negative smells that you can discover, there are more harmful chemical substances that customers cannot find but will last to affect their safety and health.

To distinguish from those microfiber towels, KINGMAX Great Towels have conducted OEKO-TEX® test and successfully pass it. Each component of our products, including the microfiber yarn, sewing thread, fabric and label, is tested to be safe.

KINGMAX microfiber products labeled as STANDARD 100 by OEKO-TEX® have been proven free of harmful levels of toxic substances and therefore harmless to human health. Our microfiber towels and mops belong to Product Class II under the STANDARD 100 by OEKO-TEX® umbrella, which means they can have direct contacts to skin and no worry about safety. Never worry to use them frequently in cleaning work.

Fine and Straight Streaks Evaporate in Five Seconds

Microfiber towels are known for its super water absorptive capacity. The split microfiber captures water and dust like a magnet and can dry any surface instantly with an easy wipe, no scratching or strain left behind.

When we take a close look at the wiping streaks left on the shiny surface, our KINGMAX Great Towels leave fine, straight and tiny streaks and these streaks instantly evaporate in five seconds in the environment under 25℃. In contrast, other microfiber towels we bought in the market leave cluttered and marbling patterns on the surface which takes a longer time to evaporate. Due to the outstanding wiping performance, we are able to announce KINGMAX Great Towel is streak-free.

High Rate of Color Fastness

Color or design is one of our preference to pick the towels among multiple choices.

KINGMAX microfiber towels have good color fastness and colors will keep as bright as original after hundreds of washing. Laundering will not affect the colors, even in high temperature up to 95℃.

| STANDARD 100 BY OEKO-TEX®Product Class II Annex 4 | #2 PES/PA Knitted microfiber fabric Piece-dyed red | #6 PES/PA Knitted microfiber fabric Piece-dyed blue | #7 PES/PA woven microfiber fabric Piece-dyed grey | |

| Colour Fastness To Rubbing OEKO-TEX® Method 20-D(EN ISO 105-X 12) Number of Tests • Staining in dry condition [grade] | >=4 | 1 4-5 | 1 4-5 | 1 4-5 |

| STANDARD 100 BY OEKO-TEX®Product Class II Annex 4 | #2 PES/PA Knitted microfiber fabric Piece-dyed red | #6 PES/PA Knitted microfiber fabric Piece-dyed blue | #7 PES/PA woven microfiber fabric Piece-dyed grey | |

Colour Fastness To Water | >=3 | 1 4-5 4-5 | 1 4-5 4-5 | 1 4-5 4-5 |

| STANDARD 100 BY OEKO-TEX®Product Class II Annex 4 | #2 PES/PA Knitted microfiber fabric Piece-dyed red | #6 PES/PA Knitted microfiber fabric Piece-dyed blue | #7 PES/PA woven microfiber fabric Piece-dyed grey | |

| Colour Fastness To Perspiration OEKO-TEX® Method 20-D(EN ISO 105-E04) Number of Tests • Fastness to acid solution • Change in color(acid) [grade] • Staining (acid) [grade] • Fastness to alkaline solution • Change in colour (alkaline) [grade] • Staining (alkaline) [grade] | >=3-4 >=3-4 | 1 4-5 4-5 4-5 4-5 | 1 4-5 4-5 4-5 4-5 | 1 4-5 4-5 4-5 4-5 |

KINGMAX has presented a new bleach-safe towel with the best color fastness (up to rate 4-5) to surpass any microfiber towel, which we call bleachable microfiber towel, as it is bleach-proof.

KINGMAX Great Towels or the bleachable microfiber towels have the top color fastness and therefore it is highly recommended for use in salon where towels would frequently contact with chemical additives.

Daily clean or professional clean with just water is sufficient, while cleaning with chemicals, KINGMAX Great Towels will be the first choice.

Comparison After Chlorine Bleaching

Durable Towel for Hundreds of Washing

KINGMAX great towels is very durable. It is made from premium AA quality microfiber materials, which not only have better cleaning features, but also extend the service life.

Especially with the real composition of 70% PES and 30% PA, the cleaning ability is great. Even after hundreds of launderings, the terry towels are still soft and fluffy.

The other important point is the KINGMAX’s signature of reinforced machine-made edges with high-quality lining and high density of stitching, all of which ensures the shape of KINGMAX towels would not easily change even after high temperature machine washing and drying procedures.

Repeated washing will not weaken cleaning ability or water absorption capacity neither.

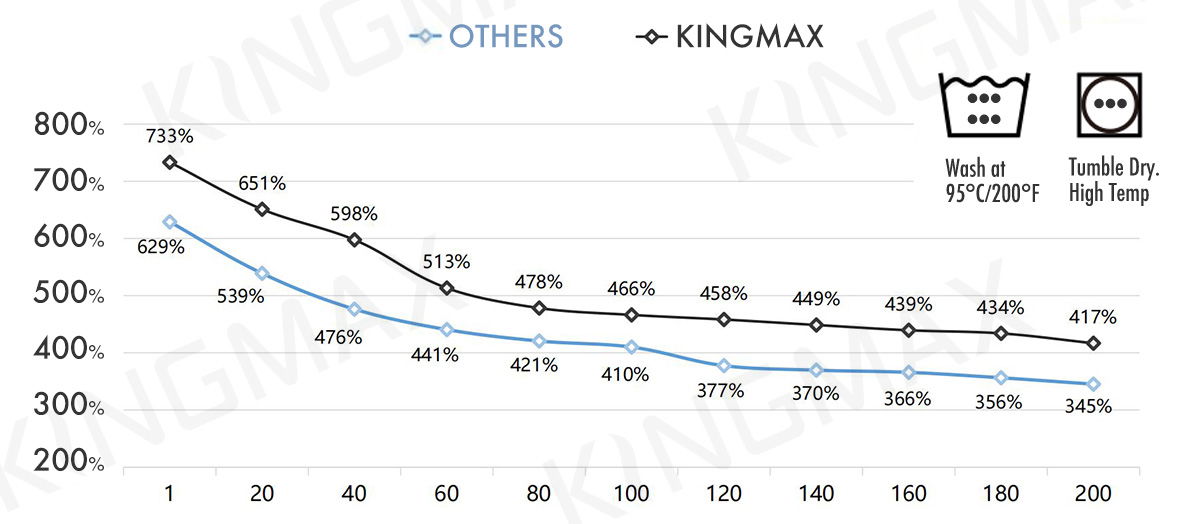

With proper care, microfiber cloths should withstand laundering over 300 times and this is reasonable for normal towels you can find in the supermarket. KINGMAX microfiber towels, moreover, have a better performance to guarantee 500 times of laundering, which is equal to 8 months of services counted by two times of laundry in one day.

The long-lasting feature of KINGMAX microfiber great towels helps to massively reduce the waste of disposable towels or kitchen tissues used in the cleaning work, therefore save a lot of cost and money.

This is also a big step to start our own contribution to save resource, reduce waste and protect the ecosystem.

AFTER 200 TIMES OF LAUNDRY

Liquid absorption till 200 washes