Recycled polyester, often called rPET, is collected from post-consume plastic bottles. It is well recognized as an innovation to divert plastic pollution from our landfills to reusable resources. Moreover, the production of recycled polyester requires far fewer resources than that of new fibers and generates fewer CO2 emissions to the Earth.

Recycled polyester is definitely a sustainable option for household textile supplies.

In this mechanical recycling, plastic is collected, granulated and melted to make new yarn for the following production. The whole process includes companies in ginning, spinning, weaving and knitting, dyeing, printing and stitching. Kingmax production sites have now been fully certified to the Global Recycled Standard (GRS).

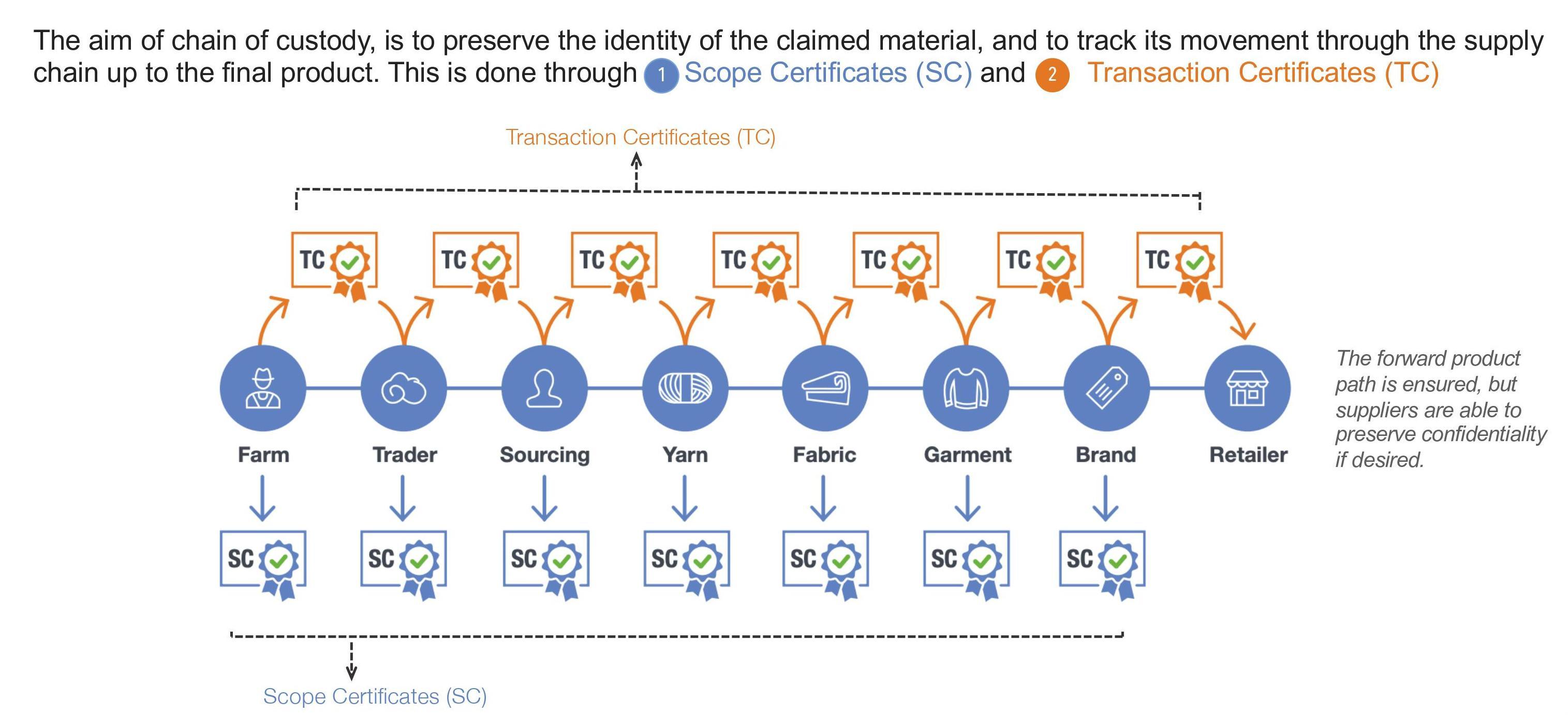

GRS is an international, voluntary, full product standard that sets requirements for third-party certification of recycled content and chain of custody (CoC). CoC requires each stage of production to be certified, beginning at the recycling stage and ending at the last seller in the final business-to-business transaction.

An important step has been achieved by Kingmax in its efforts to reduce its environmental footprint whilst providing high performance products. We have also obtained TC (Transaction Certificate), which is a certificate for the circulation of GRS certified products in the supply chain, in order to ensure the accurate production and trading of GRS certified products. That is how we put the supply chain into custody.

See more rPET collections.